The purpose of shared equipment is for multiple members to benefit from it.

Access to shared equipment is one of the most important benefits that members experience in wet lab incubators.

Without shared equipment, a startup biotech company could easily spend hundreds of thousands of dollars outfitting their lab with just the most basic necessities. Plus, it is rare for a startup to use any individual piece of equipment to its full capacity. They might need one shelf in a freezer, two shelves in a cell culture incubator, and three hours per week on the PCR machine. Therefore, shared equipment makes sense for both the incubator and the startup.

One of the most common questions that wet lab incubators get from prospective customers is, "What kind of equipment do you have?" This will vary across incubators, but there are some pieces of equipment that are standard for almost all wet labs. Here we will cover:

🔬 Read more about: Lab Space for Biotech Startups.

One of the most important and most common pieces of shared equipment in a wet lab incubator is a freezer. Cold storage is essential for most biotech companies, but startups will frequently not fill an entire freezer or refrigerator on their own. Therefore, wet lab incubators provide shared ultralow freezers, -20C freezers, and refrigerators to their members. Usually a set amount of space per company will be assigned and members pay to use additional space. An additional benefit of utilizing shared cold storage is that most incubators monitor their cold storage units in case of power outage or compressor failure. This means that if there is a problem with a freezer, the incubator staff will be alerted and able to take action on behalf of all their members, rather than each startup individually having to monitor freezers and respond to alerts.

Another very common type of shared equipment is what we’ll call general wet lab tools. These pieces of equipment can be used for many types of science including chemistry, molecular biology, cell biology, and microbiology. Analytical scales, vortexers, heat blocks, centrifuges, pH meters, hot plates, magnetic stir plates, water baths, and other types of benchtop equipment that are used across many types of labs fall into this category. These items are not particularly expensive, but it is convenient to have them available when needed.

🔬 Learn more: 11 Equipment & Amenities Every Wet Lab Incubator Needs

Less general in use but still common are pieces of equipment for molecular biology applications. These include PCR machines, gel electrophoresis apparati, Western blot imagers, gel documentation stations, and plate readers. Microbiology is another common application in wet lab incubators, so they usually will supply high speed centrifuges, shaking incubators, regular bacterial incubators, autoclaves, and bunsen burners. In other words, incubators usually have all the equipment needed to clone plasmids.

One of the most commonly requested types of equipment in wet lab incubators is for cell culture. Startups that need to manipulate or grow mammalian cells (especially human cells), must do so in biosafety cabinets in order to prevent the cells from being contaminated. And in the case of human cells, OSHA requires these hoods to be used in order to prevent any potential bloodborne pathogen transmission to the scientists. Therefore, many wet lab incubators provide dedicated rooms equipped with biosafety cabinets, cell culture incubators, water baths, refrigerators, centrifuges, and inverted microscopes where startups may complete their cell culture experiments. Also frequently needed by the same companies that perform cell culture are high powered microscopes. Microscopy can be one of the most expensive categories of equipment, but it is essential for cell biologists and others who need high-quality images. Most incubators will have at least one or two microscopes besides the inverted scope in their cell culture room.

Finally, chemistry equipment is another common category for wet lab incubators to provide. However, within this category it's hard to generalize which items most incubators will have. The exception being fume hoods, which almost all incubators will have at least one of.

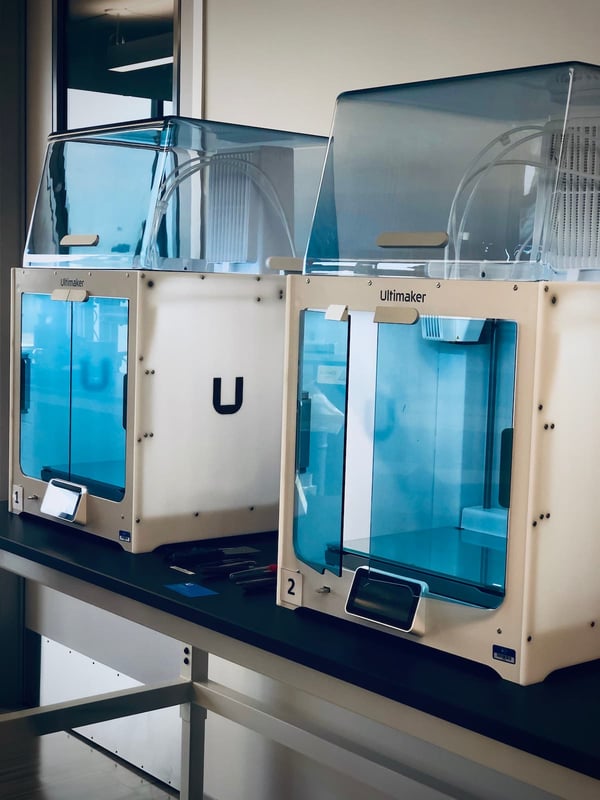

A bonus category would be anything that may be useful for medical device companies. This can include basic 3D printers, soldering stations, and hand tools. However, medical devices come in so many varieties and require such expensive equipment that it would be impossible to provide a broad selection of items.

🔬 Learn about: Wet Lab vs. Dry Lab for Your Life Science Startup

Another question that prospective incubator members ask is whether the equipment is maintained to a widely recognized quality standard, such as ISO. However, it is impractical for most wet lab incubators to pursue accreditations and maintain such standards. Not only do these accreditations cost significant money, but they also require much more oversight than is practical in a shared-use setting. In general, every member who uses the equipment would have to follow the potentially stringent protocols for training, use, and documentation. Incubators would not be financially viable if they had to have a staff member monitor the equipment constantly to be sure protocols are being followed.

Incubators are designed primarily for research and development purposes so startup biotech companies can determine if their technology can be turned into the product they plan to sell. This means companies may be trying many different protocols using a single piece of equipment and not have time to validate each one. They may take in interns who have been trained to use the equipment, but internships are expected to be a learning experience and learning equals mistakes.

Because of the impracticality of keeping incubator equipment up to ISO, GMP, IQ OQ PQ, or any other standard or method of quality assurance, companies that require this are better off purchasing their own equipment and either choosing an incubator where they can rent a private lab or building out their own lab space.

Just because incubators don’t maintain ISO standards doesn’t mean they don’t maintain their equipment. In fact, equipment maintenance is another significant benefit of working with an incubator. Equipment is not only expensive to purchase, but preventive maintenance can also cost a significant amount. Some startups will skip paying for preventive maintenance in order to save money, but find out later that their equipment was out of alignment and have to repeat experiments, effectively negating the initial savings. Incubators generally have preventive maintenance contracts for equipment that requires special training to upkeep and will perform regular maintenance themselves on other items. Less time spent cleaning out water baths and calibrating analytical balances means more time for each startup to spend on their primary work.

While preventive maintenance does help avoid future problems with equipment, it is inevitable that something will eventually break and require repairs. Although broken equipment is always inconvenient, incubators arrange repairs for their shared equipment and make sure that members know what is broken and the estimated timeline for repairs. This saves startups time and keeps unexpected expenses low. Furthermore, many incubators are well connected in their local communities and may know of local laboratories that are willing to allow members on site to use a piece of equipment while the incubator’s is being fixed.

A note on new versus used equipment: Biotech incubators are split in terms of whether they purchase mainly new or used equipment. Used equipment is not necessarily a negative, since just as computers are expected to be replaced ever more frequently, new lab equipment is not necessarily built to last for as long as equipment that was made decades ago. There are plenty of instances where a 20-year-old centrifuge will outlast a 2-year-old one. Quality should not necessarily be judged by the age of the equipment, but rather by how well it is maintained.

🔬 Learn more: 11 Reasons Why Lab Space is So Expensive

The nature of shared equipment requires cooperation, and incubators usually have methods to streamline this process. By providing ways to schedule certain types of equipment use, incubators help to make sure their members can use what they need when they need it. This does require startups to plan out their experiments, especially if a piece of equipment is in high demand. However, scheduling can also allow the incubator to see when a piece of equipment is being used heavily, which can factor into decisions about buying new equipment.

Although wet lab incubators do their best to guess what pieces of equipment will be the most useful for their members before they ever open, there will always be pieces that they don’t have. Generally, incubators will have policies on how they determine whether or not to purchase a new piece of shared equipment. Except in very rare circumstances, most incubators do not purchase equipment that only one member is expected to use. The purpose of shared equipment is for multiple members to benefit from it, so unless the incubator believes that a particular item will help to attract new members, they only buy items that more than one member requests. Incubators may solicit suggestions from their members or simply consider requests that members make as they come up.

One way incubators think about this is that if a piece of equipment is central to a startup’s work, that company should probably think about buying their own. Shared equipment is meant to benefit the community, not just one group.

🔬 Read more about: Buying New Lab Equipment

Even in a wet lab incubator with a large amount of shared equipment, it is expected that companies will bring in items of their own. This can be for a few reasons, such as the item is small and so ubiquitous that it would be inconvenient to have to share it. A good example of this is micropipettors--they are as necessary as pens to many startup biotech companies. Another reason is that some companies want the convenience of having their own equipment so they don’t have to walk over to the shared item, or so they don’t have to worry about other companies’ schedules. It can be nice to have a vortexer on your own bench, for instance. Sometimes a piece of equipment is so essential to the startup’s technology that they don’t want to use a shared item in case someone breaks it. And finally, some startups bring in their own equipment simply because they already have it and otherwise would have to put it into storage.

Most incubators are fine with companies bringing in their own equipment as long as it is approved. Approval usually depends on how large the item is, what its utility requirements are, whether it may be contaminated with substances that are not allowed on site (radioactive material, certain kinds of biohazards, etc.). For equipment that does not fit in a member’s designated space, some incubators will allow floor standing equipment to be placed next to a bench or in another designated area, possibly for a fee. If the piece of equipment is something that other members are interested in using, some incubators will waive the placement fee if the item may be shared with those other companies. With equipment that has a cost associated with running it or that requires technical training, incubators may allow or even facilitate fee-for-use services. Flow cytometry usually requires a trained technician to run the equipment, so this is a prime example where one company might charge a fee to run samples for other companies.

The information presented in this article is meant to give you a general idea of what to expect in terms of equipment at wet lab incubators. However, it is important to ask about each of the above topics and to make sure you and any incubator you choose to work with understand the expectations around laboratory equipment. Ask for the incubator’s equipment list, how it’s maintained, how it’s scheduled, how they decide on new equipment, and whether you can bring your own. Knowing what to expect will make your experience with any incubator much smoother.

9 Reasons why Startups Need Incubators

Download The Ultimate Guide to Wet Lab Incubators in Southern California, a handbook to assist life science start-ups through the entire decision-making process to find wet lab space.

Download Now